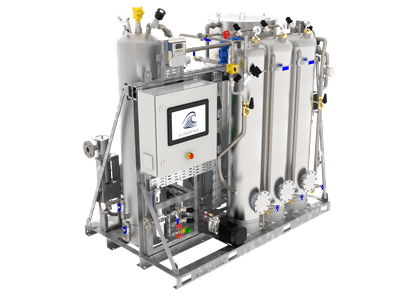

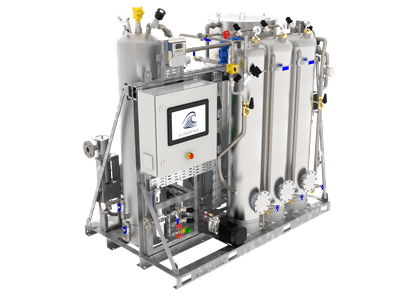

Marinfloc bilge water separator

Marinfloc’s bilge water separator stands apart by using flocculation technology, delivering clean water overboard below 5 ppm, fully compliant with MEPC 107(49). With a capacity of 0.25 to 5 m³/h, it operates at low energy consumption, helping shipowners reduce CO₂ emissions while ensuring reliable bilge water treatment.

Effective Oily Water Treatment

The CD unit is a highly trusted bilge water treatment system, utilized in over 700 vessels worldwide (both newbuildings and retrofits). It features a dissolved air flotation and flocculation technology, with a capacity range from 0.25 to 5 m3/h. What sets it apart is its ability to consistently treat bilge water to below 5 ppm, ensuring compliance with MARPOL standards. Designed with onboard practicality in mind, it features an intuitive HMI screen for user-friendly operation and adaptability to diverse bilge water compositions. We also take pride in having the lowest operational expenses on the market.

At Marinfloc, we understand the challenges faced by ship operators, and we've recognized the issue of outdated bilge water separators. These separators, ill-equipped for today's and yesterday's fuels, put ship operators in a difficult position. When onboard equipment falls short of modern standards, it compromises legal compliance and environmental safety.

Our CD unit is designed with the crew in mind. The use of flocculation technology, typically employed on land to treat wastewater containing emulsions, allows the crew to effectively handle the diverse mixtures that end up in the bilges. With over 25 years of experience, our satisfied customers have demonstrated that superior performance is not just possible, but easily achievable.

Marinfloc is here to assist. Our separators are engineered to ease the burden on ship operators, providing them with the right tools for both our oceans and their business.

Utilizes flocculation technology, eliminating the need for cartridge filters and centrifuges.

Adaptable to treat any specific composition of a ship’s bilge water.

Type-approved to 5 ppm with Deckma

Designed for low energy consumption, contributing to reduced carbon footprints.

Easy to install, easy to retrofit

Touchscreen control cabinet available for smart functions and online connectivity

Offers a low operational cost, ensuring value for money.

Utilizes flocculation technology, eliminating the need for cartridge filters and centrifuges.

Adaptable to treat any specific composition of a ship’s bilge water.

Type-approved to 5 ppm with Deckma

Designed for low energy consumption, contributing to reduced carbon footprints.

Easy to install, easy to retrofit

Touchscreen control cabinet available for smart functions and online connectivity

Offers a low operational cost, ensuring value for money.

Unwavering support. Top-notch training.

Safer waste streams and better workflow. At Marinfloc, we are dedicated to helping you manage and minimize the maintenance of your onboard wastewater systems.

Operating principle

The Marinfloc system is a fully automatic bilge water cleaning solution, utilizing flocculation to effectively handle stable chemical emulsions. This pioneering system was the first to receive approval according to IMO resolution MEPC.107(49) and boasts certifications from the U.S. Coast Guard and major classification societies, including a type-approval from DNV's 5 ppm program.

The process of the system includes:

Oil Separation: The system separates free oil from water through gravitational methods in the oil descaler. Accumulated oil is then transferred to the vessel’s sludge tank once detected by an oil sensor.

Aeration: Compressed air is introduced into the circulating tank, mixing with the water to dissolve air maximally. This process helps in the continuous discharge of bilge water, maintaining the system's operation.

Flocculation and Forced Flotation (DAF): In this stage, water is directed to the flocculation tank where chemical dosages are precisely controlled for optimal flocculation. A layered separation occurs, with a foam layer being continuously removed to the sludge tank.

Filtration: The filtered water, now clearer but possibly slightly discolored, passes through a series of filters to reach an effluent quality of <15 ppm. This comprehensive filtering stage ensures the removal of any remaining contaminants, including oil and flocks.

Additionally, an Oil Content Meter (OCM) is incorporated to ensure compliance with environmental regulations by monitoring the oil content in the water, which is typically set to not exceed 15 or 5 ppm.

Flocculation is a water treatment process in which solids come together to form larger clusters, or flocs, which are then removed from the water. This process can occur naturally or with the assistance of chemical agents. It is a common method of wastewater treatment and drinking water purification.

DAF is a water treatment technique that removes suspended particles like oil or sediments from liquids. By dissolving air under pressure and releasing it at atmospheric pressure in a flotation tank, tiny air bubbles attach to the particles, making them float to the surface for removal.

No other waste stream on a ship is so closely connected to million-dollar fines and imprisonment as bilge water. Bilge water contains various pollutants from the engine room, not just oil and water. Marinfloc has the expertise, technology, and flexibility to provide tailored solutions for your needs.